The TEP Package

Software Selection Tool - Materials

There are over 40

materials included in the software, grouped into 5 classes,

providing a wealth of information.

There are 2 levels of information, one for

material classes and one for individual materials.

The information on material classes is split into

2 sections:

A description of the

general characteristics of the class

A table of process compatibilites

detailing how suitable the class is for manufacturing

with the various processes included in the processes area.

The information on individual materials is split

into 5 sections:

- An overview giving useful general

information about the material

- Design issues detailing the specific

strengths and weaknesses of the material in a design

context

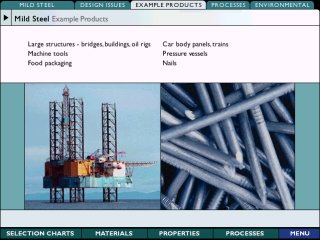

- A list of example products made with

this material and some representative pictures.

- A table of process compatibilites

detailing how suitable the material is for manufacturing

with the various processes included in the processes area.

- Some of the important environmental issues

associated with the material.

Materials included:

- Metals and alloys: Mild Steels, Alloy Steels,

Stainless Steels, Cast Iron, Aluminium alloys, Copper,

Brasses, Nickel alloys, Titanium alloys, Magnesium

alloys, Zinc, Lead, Gold

- Ceramics: Glasses, Alumina, SiC, Silicon,

Diamond, Zirconia

- Porous Ceramics: Brick, Porcelain, Concrete

- Polymers: Polythene, Polystyrene, Polypropylene,

PMMA, Polycarbonate, PVC, ABS, Nylon, PET, Urea

Formaldehyde, Polymer foams, Rubber

- Composites: GFRP, CFRP

- Wood and wood products: Pine, Balsa, Oak, Medium

density fibreboard (MDF), Paper

Return to overview of TEP

software selection tool

Return to overview of TEP

software selection tool

Last updated: 17/03/2000. Please email any comments to: Andrew Lovatt

![]() Return to overview of TEP

software selection tool

Return to overview of TEP

software selection tool