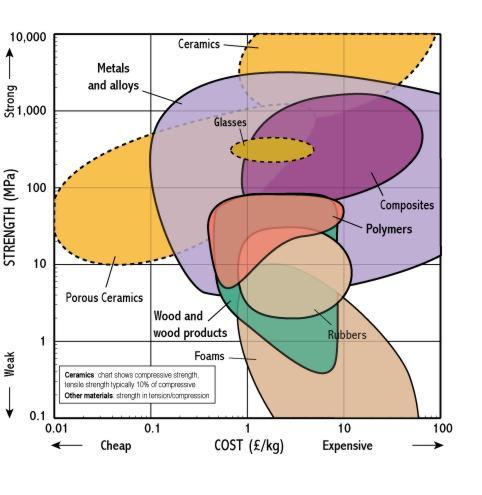

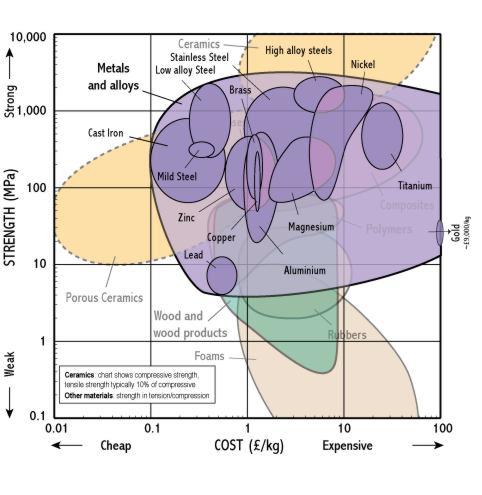

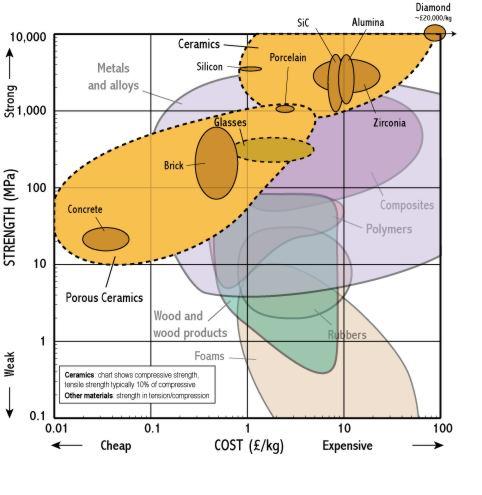

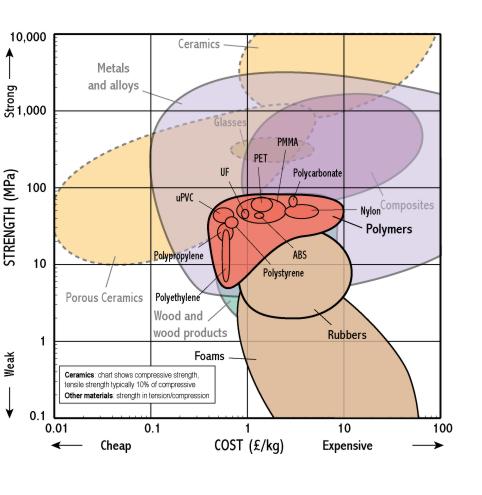

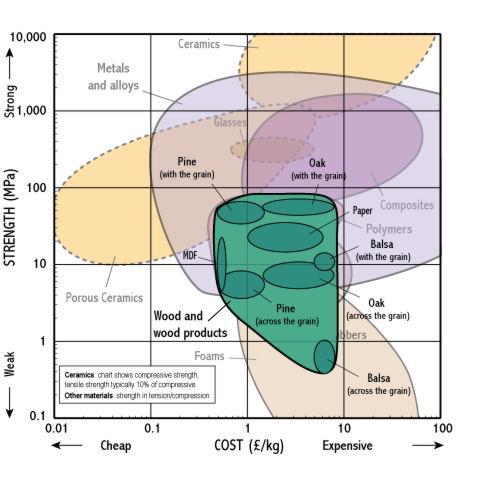

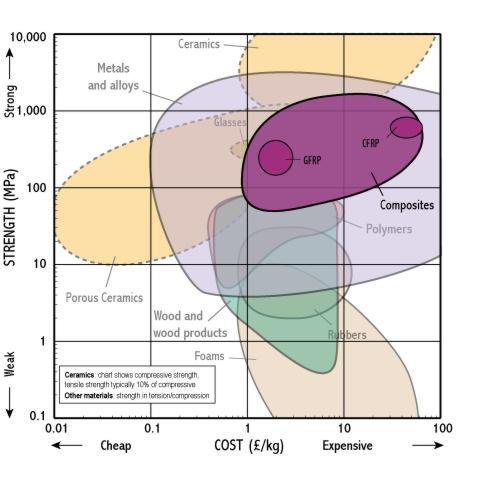

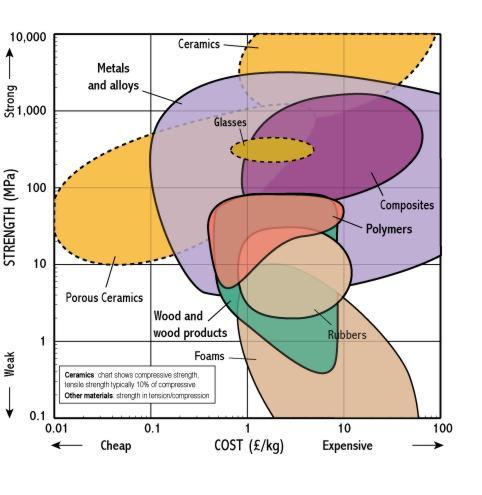

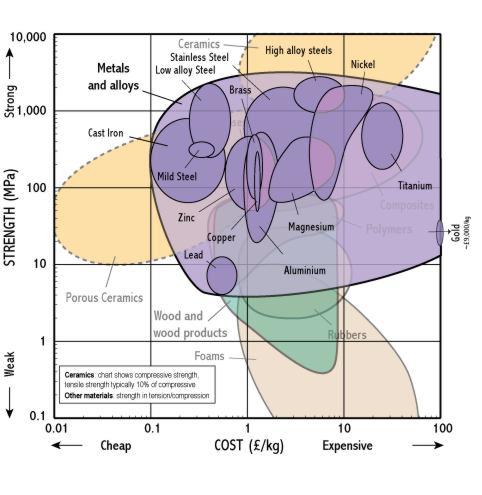

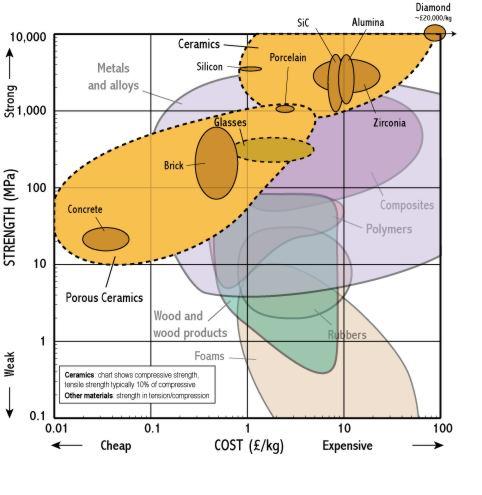

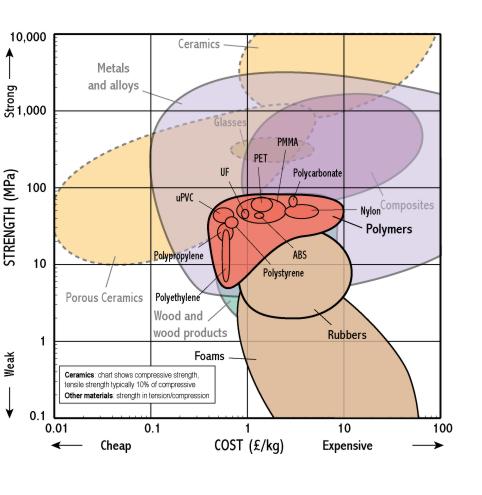

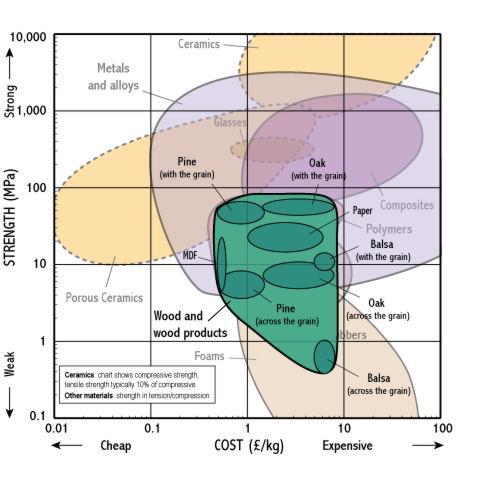

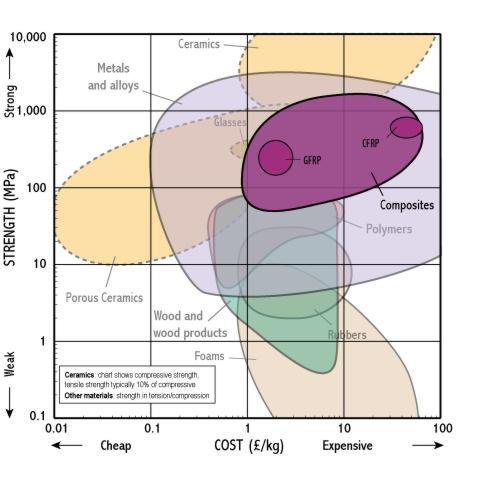

Strength - Cost

Class level

Metals and alloys

Ceramics

Polymers

Wood and wood products

Composites

General Information

- Strength measures the resistance of a material to failure, given by the applied stress (or load per unit area)

- The chart shows yield strength in tension for all materials, except for ceramics for which compressive strength is shown (their tensile strength being much lower)

- Many applications require strong materials, e.g. screw drivers, safety belts - these lie at the top of the chart

- Unfortunately there are few cheap high strength materials (top left)

Physical Insights

- Ceramics and glasses have directional covalent bonds. They are weak in tension because they are sensitive to small cracks or flaws.

- Metals do not have directional bonds and have similar tensile and compressive properties

- Cellulose microfibres make wood strong in tension along the grain

- Alloys are much stronger than pure metals

- Metals can be strengthened by heat treating to change the microstructure

Example Uses

- Teflon as a non stick surface for frying pans

- Ceramic for fire bricks and for coatings for jet engine blades

- Tungsten for light bulb filaments

Simple Questions

- Why is wood used for beams rather than stone, when stone has a higher strength?

- Why is pottery weak?

- Why is steel the most commonly used ‘strong’ material?

- Select materials for a screwdriver.

- Select materials for a glass-cutting tool.

Further Questions

- Why can polymers operate only at low temperatures when their polymer chains contain covalent bonds like ceramics?

- What is the operating temperature of a light bulb filament?

There are 2 separate populations for this class to improve clarity. Move the mouse over different parts of the class name to reveal each one.

Select chart: