Process Encyclopaedia

Forging

Other names / variants: ring-rolling, open-die forging, closed-die forging, drop forging

Related processes in this database include: metal extrusionOverview

- Forging is probably the oldest metalworking process - dating back to at least 5000BC.

- It has advanced a long way from its "blacksmith" image and today there are many hi-tech variants that compete mainly with the casting processes.

- Although forging can take place "cold", the component is usually heated to reduce the forces required.

- The forging action can be extremely noisy!

Variants

- Impression Die Forging - also called closed die forging, presses metal between 2 dies that contain a precut profile of the desired part.

- Cold Forging - includes bending, cold drawing, cold heading, coining, extrusions and more, to yield a diverse range of part shapes. The temperature of metals being cold forged may range from room temperature to several hundred degrees.

- Open Die Forging is performed between flat dies with no precut profiles is the dies. Movement of the work piece is the key to this method. Larger parts over 20 tonnes and 10 metres in length can be hammered or pressed into shape this way.

- Seamless Rolled Ring Forging is typically performed by punching a hole in a thick, round piece of metal (creating a donut shape), and then rolling and squeezing (or in some cases, pounding) the donut into a thin ring. Ring diameters can be anywhere from a few inches to 30 feet.

Process details

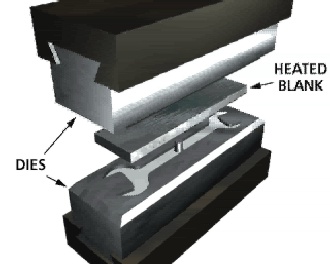

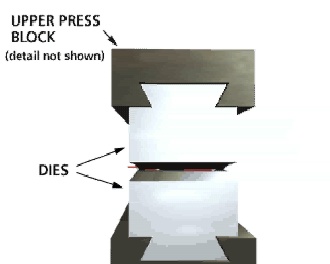

Closed-die forging

A heated blank is placed between 2 halves of a die

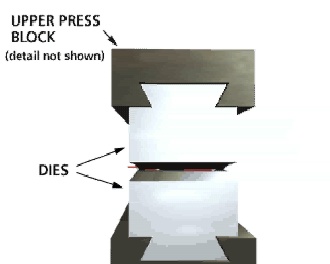

A single compressive stroke squeezes the blank into the die to form the part. In hammer or drop forging this happens by dropping the top of the mould from a height. An alternative is to squeeze the moulds together using hydraulic pressure.

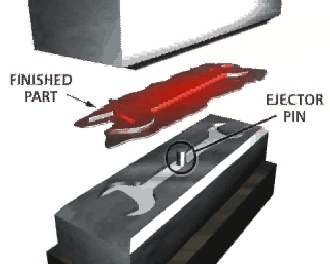

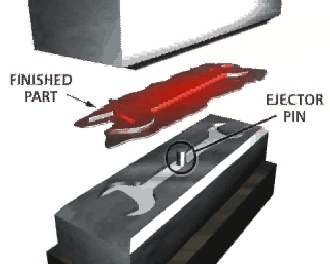

Once the die halves have separated, the part can be ejected immediately using an ejector pin.

The waste material, flash, is removed later.

Materials and shapes

- Any metal can be forged, provided the blank is hot enough (( 60% of the melting temperature).

- Typical possible sizes for closed dies range from 10g to 10kg, depending on complexity.

- The part is left with good surface and mechanical properties, although cold-forging can perform even better.

- Complex parts can be formed using a series of forging dies with increasing levels of detail.

- A draft (taper) angle has to be incorporated to allow easy removal of the part.

- Any waste material squeezed between the die halves, called flash, is readily recycled.

Economics

- Production rate is limited by the insertion and removal of the blank, so some form of automation is often used.

- As a result, machines can cost £100,000+, but can produce many parts a minute (if small).

- As both the machines and the dedicated dies are costly, production runs in excess of 50,000 are often needed to produce small parts economically.

- Large parts can be produced economically at smaller batch sizes, because there is less competition.

Typical products

- Spanners

- pedal cranks

- gear blanks

- valve bodies

- hand tools

- crankshafts

- coins

External links