Property Information

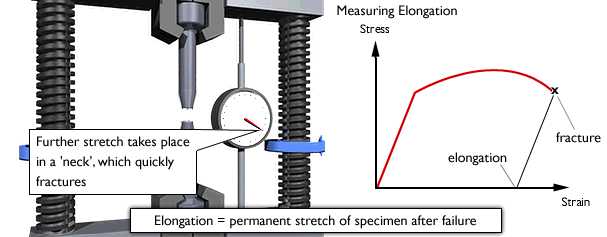

Elongation

Overview

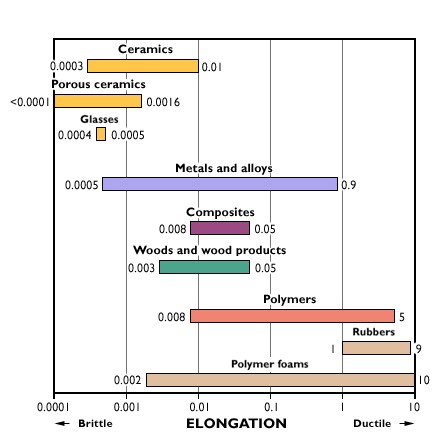

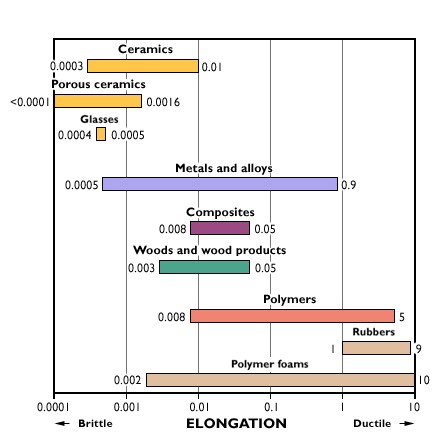

- Elongation to failure is a measure of the ductility of a materials, in other words it is the amount of strain it can experience before failure in tensile testing.

- A ductile material (most metals and polymers) will record a high elongation. Brittle materials like ceramics tend to show very low elongation because they do not plastically deform.

- Rubber extends by a large amount before failure, but this extension is mostly elastic and is recovered.

Design issues

- Elongation is important in components which absorb energy be deforming plastically (e.g. crash barriers, car bumpers).

- High elongation to failure is important for "plastic hinges" (e.g. video cassette boxes).

- Elongation is important in manufacturing - it measures how much bending and shaping a material can withstand without breaking.

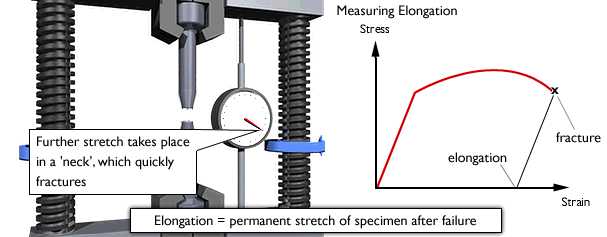

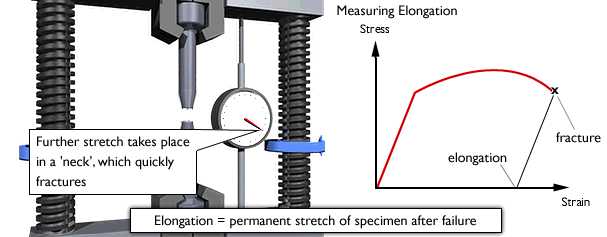

Measurement

Tensile testing is used to find many important material properties. The compression test is similar but uses a stocky specimen to prevent bending.

Units & Values

Because elongation is equal to the failure strain it has no units, but is often given in % strain.