Property Information

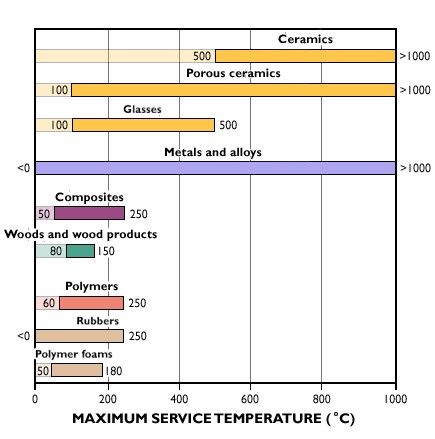

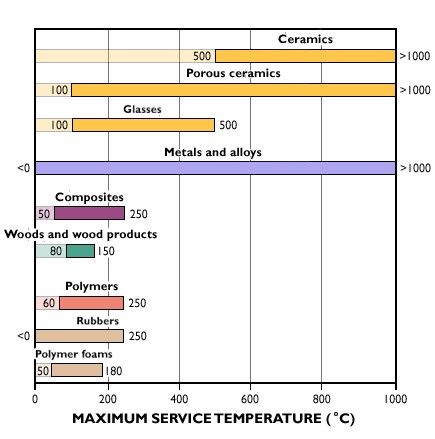

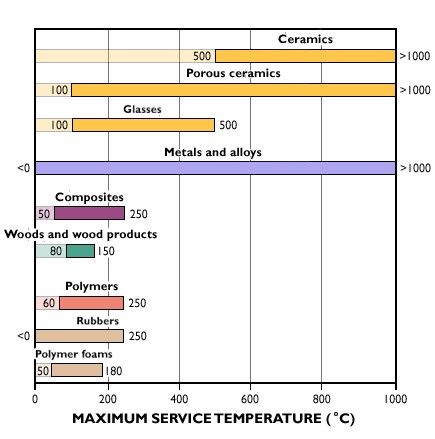

Maximum Service Temperature

Overview

- The strength of a material tends to fall quickly when a certain temperature is reached. This temperature limits the maximum operating temperature for which the material is useful.

- For metals the maximum operating temperature is usually around two thirds of the melting temperature.

- For prolonged loading the maximum stress will be lower because creep (permanent stretching over time) will occur.

- The data for a material on the selection chart shows the range in which the maximum service temperature fall (since a given "material" on the chart will include many different variants with the same name).

- Note that the range of maximum service temperature does not mean the range of temperature in which the material must be used! It may be assumed that any operating temperature below the maximum service temperature down to zero degrees Centigrade is safe in design.

- Problems can occur when materials are used well below 0oC - for example special steels must be used to contain liquified gases, since ordinary carbon steels may become brittle at these very low temperatures.

Design issues

- The maximum service temperature is important for applications where components become hot. Jet engines, brake discs and extrusion dies are all examples of products which operature at temperatures of 400oC or more - metals and ceramics are then required. Temperatures of only 100oC are enought to cause problems for lower melting point materials such as polymers - for example, plastic cups and kettles.

- If the load is applied for many hundreds of hours then the design loads must be lowered because the material is liable to creep. Creep is the slow permanent stretch of a material at temperatures approaching the melting point, which leads to failure by tearing or fracture.

- For the nickel alloys used in jet engines, creep only occurs at temperatures above 600oC, but polythene shopping bags creep and fail at room temperature if the weight of the shopping is too large.

Measurement

The maximum service temperature is found by measuring the strength at different temperatures. A series of tests are carried out with the specimens in a furnace. Well below the maximum service temperature the strength only varies a little. The temperature at which the strength starts to fall sharply is defined as the maximum service temperature.

Units & Values

- The maximum service temperature is measured in Kelvin (or degrees Centigrade).

- Note that the range of maximum service temperature does not mean the range of temperature in which the material must be used! It may be assumed that any operating temperature below the maximum service temperature down to zero degrees Centigrade is safe in design.