Property Information

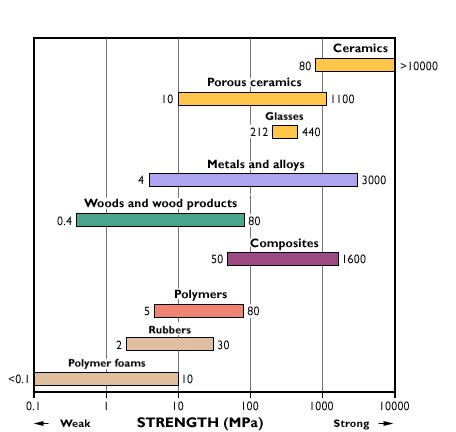

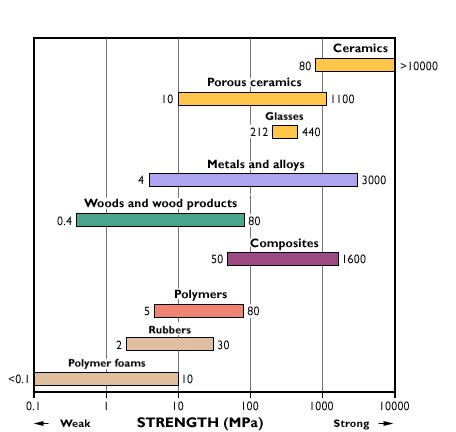

Strength and Specific Strength

Overview

- The strength of a material is its resistance to failure by permanent deformation (usually by yielding).

- A strongmaterial requires high loads to permanently deform (or break) it - not to be confused with a stiff material, which requires high loads to elastically deform it.

- For metals, polymers, woods and composites, "strength" on the selection charts refers to loading in tension (as failure is by yielding).

- For brittle materials (ceramics), failure in tension is by fracture, and the "tensile strength" is very variable. The "strength" on the selection charts is then "compressive strength" (which requires a much higher load).

- Specific strength is strength divided by density.

Design issues

- Many engineering components are designed to avoid failure by yield or fracture (cranes, bikes, most parts of cars, pressure vessels).

- In structural applications, brittle materials are nearly always used in compression (e.g. brick, stone and concrete for bridges and buildings).

- In transport applications (e.g, aeroplanes, racing bikes) high strength is needed at low weight. In these cases materials with a large "specific strength" are best.

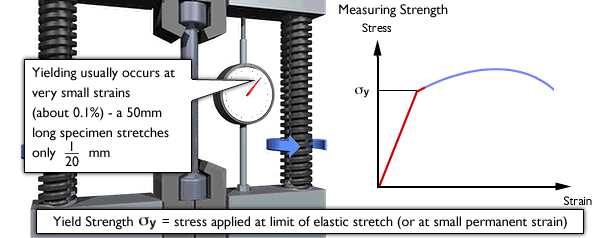

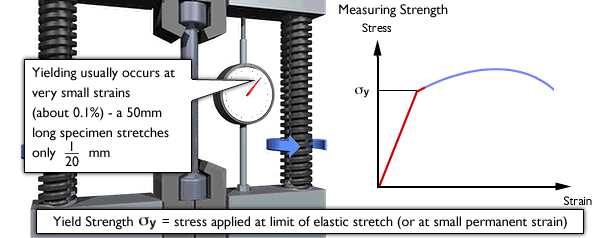

Measurement

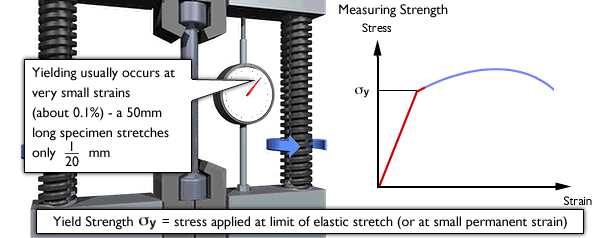

Tensile testing is used to find many important material properties. The compression test is similar but uses a stocky specimen to prevent bending.

Two measures of strength are defined - yield strength and ultimate tensile strength. Strength on the selection charts means yield strength.

Units & Values

Strength is measured by applied stress, which is equal to force/area. The units of stress are N/m2 or Pascals (1 Pa = 1 N/m2 ; 1 MPa = 1 N/mm2

Specific strength is strength/density - it is mostly just used for comparing materials, so the units are not important.