Overview |

Design Issues |

Measurement |

Units & Values |

|---|

Overview |

Design Issues |

Measurement |

Units & Values |

|---|

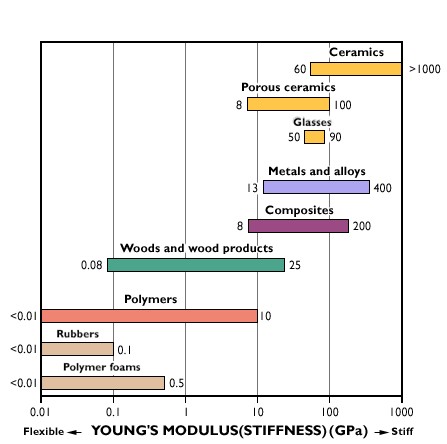

Specific stiffness (more properly called specific modulus) is Young's modulus/density - it is mostly used for comparing materials so the units are not important.