|

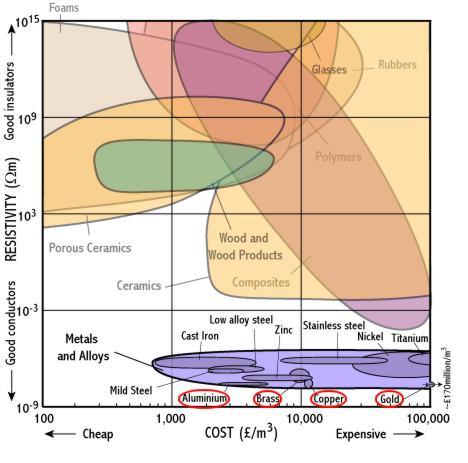

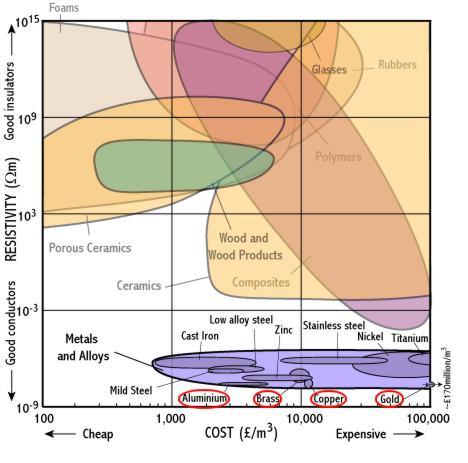

Resistivity - CostThe materials with the lowest values of resistivity are aluminium, brass, copper and gold. All these are commonly used as conductors in practice, although clearly gold is a bit too expensive for use in a plug! Also, although aluminium is a good conductor, it is not suitable for a removal plug because it develops an insulating oxide layer. So, how to choose between copper and brass? The strength-toughness chart helps to answer this... |

|

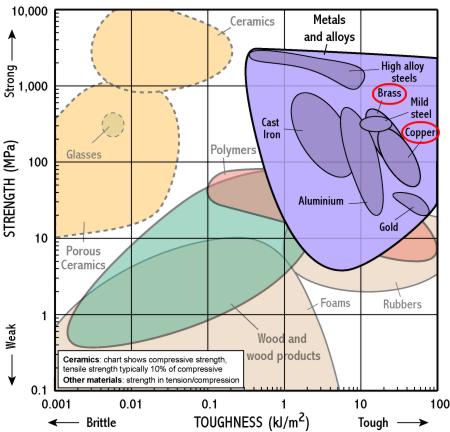

Strength - ToughnessWe can see from this chart that brass has higher strength and hence better wear resistance than copper. So, brass is used for the pins because it is the best compromise between the three competing needs for low cost, good electrical resistivity and good wear resistance. Brass is an alloy of copper; it is common for alloys to have higher strength than the pure metal. The higher strengths in the copper bubble only come from 'cold working' which would be expensive, so brass is even more attractive than it first appears. |