![]() Download this document in B&W printable form

(PDF

format).

Download this document in B&W printable form

(PDF

format).

|

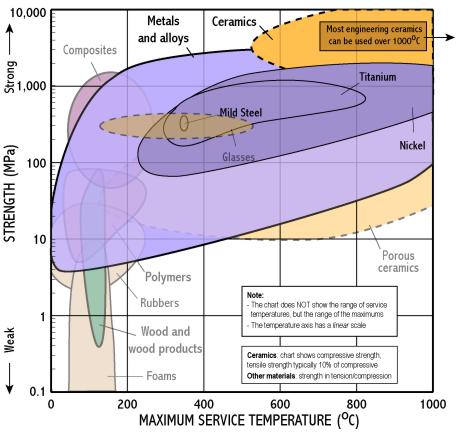

The past shows the future will be hotterThe figure on the left shows that the remarkable improvements in aero-engine performance have come about because the materials designer has been able to provide the engineer with materials can be used at hotter temperatures. Higher engine temperatures are needed so that the engines can run more efficiently, while weight reductions require stiffer, stronger, and lighter materials. |

If you can't stand the heat!The hot parts of the engine require materials which can operate at 1000°C, the cooler parts at 600°C. Furthermore, the environment is very harsh chemically and mechanically, with very large forces generated by the high rotational speeds and even the possibility of birds being sucked into the engine! The maximum service temperature chart (on the right) is a useful way of identifying new possibilities for materials development. By drawing lines at 600°C and 1000°C it is possible to identify the materials classes which might be suitable in this case, namely metals and ceramics. At the present time titanium and nickel alloys are used for the low and high temperature parts. |

|

To see why ceramics, which appear to have the best high temperature properties, are not used in aero-engines it is helpful to consider other properties which are important.

Property |

Metals |

Ceramics |

| Toughness (bird strikes) | Good | Very Poor |

| Oxidation/corrosion resistance | Fair | Good |

| Forming | Good (forging) | Fair (sintering) |

| Joining | Good | Difficult |

| Creep resistance | Fair | Good |

| Cost | High | High |

Poor toughness is the main reason why ceramics have not been successfully introduced into the majority of engines, but research continues.

|

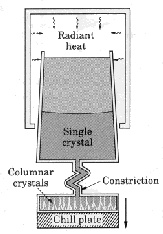

The tricks Materials Scientists playMaterials scientists have worked hard to increase the operating temperature of today's alloys:

|

|

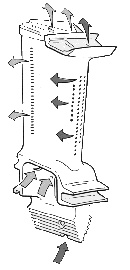

While ceramics cannot yet be used for major components, Zirconia (ZrO) coatings are being used to increase the operating temperatures. These coatings can operate at much higher temperatures and protect the metal from chemical attack.

Oxides (e.g. ZrO, Al2O3) are often used for high temperature coatings. Combined, the effects of air cooling and ceramic coatings mean that the combusting gases can reach temperatures over 1600°C - higher than any metal can work.