![]() Download this document in PDF

format.

Download this document in PDF

format.

The most important design consideration for helmets is their ability to survive impacts. These impacts can vary from falling objects to head-on collisions. The helmet lessens the impact by absorbing energy - but it turns out that the best way of doing this, and the best materials, depends on the type of impact.

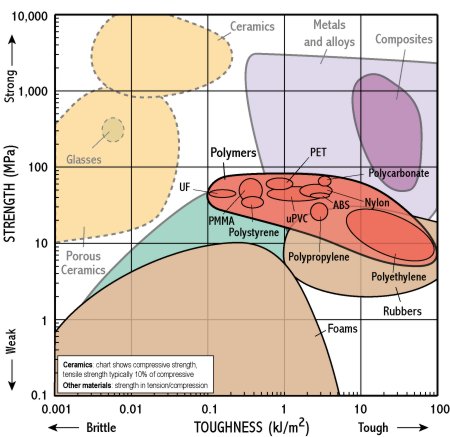

Workers on a building site or in dangerous factories must wear a hard hat. This is to prevent injury caused by impacts from small falling objects such as tools or small stones dropped by those working overhead - no helmet will protect from a falling girder! The key requirement here is that the helmet must not break under the impact. The materials used must have good toughness so they do not fracture (crack), and enough strength to take the maximum load without deforming.

The selection chart helps identify materials that have high toughness and sufficient strength. Composites, most metals, and many polymers look good. Another requirement for hard hats is that they should be inexpensive and low weight. Polymers best meet all these needs and are also easy to manufacture. In fact hard hats are mainly made from polycarbonate or ABS and fitted via adjustable polyethylene straps inside the shell.

|

The

requirements for a climbing helmet are similar to those

of a hard hat (although a climber must be able to rely on

their helmet even after it has suffered an impact). The

first designs for climbing helmets were, therefore, not

much different from a hard hat. Since then, considerable

effort has been put into making climbing helmets more

comfortable and lighter in weight. The shell is often

still made of polycarbonate, but as cost is less

of an issue new materials like glass fibre or carbon

fibre reinforced polymer (GFRP/CFRP) composites are

now being used to reduce weight. Helmets can be made more

comfortable by producing a wider range of shapes and

including a liner (usually made of a nylon fabric). The

requirements for a climbing helmet are similar to those

of a hard hat (although a climber must be able to rely on

their helmet even after it has suffered an impact). The

first designs for climbing helmets were, therefore, not

much different from a hard hat. Since then, considerable

effort has been put into making climbing helmets more

comfortable and lighter in weight. The shell is often

still made of polycarbonate, but as cost is less

of an issue new materials like glass fibre or carbon

fibre reinforced polymer (GFRP/CFRP) composites are

now being used to reduce weight. Helmets can be made more

comfortable by producing a wider range of shapes and

including a liner (usually made of a nylon fabric). |

As well

as protecting from small knocks, a cycle helmet must

protect against the large impact on the head received

during a crash. In this case it doesn't matter if the

helmet is permanently damaged (all manufacturers

recommend replacement after an accident), but it must

absorb lots of energy. The best materials for this are

foams - they absorb lots of energy when they are crushed.

The main impact absorbing material in a cycling helmet

is, therefore, a moulded block of polystyrene foam,

usually with a polycarbonate covering. These

materials are easily shaped - cycling helmets often have

striking shapes to improve their aerodynamic performance. As well

as protecting from small knocks, a cycle helmet must

protect against the large impact on the head received

during a crash. In this case it doesn't matter if the

helmet is permanently damaged (all manufacturers

recommend replacement after an accident), but it must

absorb lots of energy. The best materials for this are

foams - they absorb lots of energy when they are crushed.

The main impact absorbing material in a cycling helmet

is, therefore, a moulded block of polystyrene foam,

usually with a polycarbonate covering. These

materials are easily shaped - cycling helmets often have

striking shapes to improve their aerodynamic performance.

|

All helmets are made from a number of components: an outer

shell, an inner liner (for good fit and comfort), fitting straps,

and perhaps a decorative covering.

Helmet shells are made by blow moulding, vacuum moulding or

injection moulding. In many cases the relatively thin section of

the outer shell lends itself to sheet process technologies.

|