![]() Download this document in B&W printable form

(PDF

format).

Download this document in B&W printable form

(PDF

format).

Before the advent of non stick frying pans steel was the preferred material for spatulas, but it is too hard (strong) for delicate teflon finishes.

Wood is also used for spatulas, but it is not possible to make it as thin as with steel so they are not as versatile.There can also be hygiene problems because wood can split and food can become trapped.

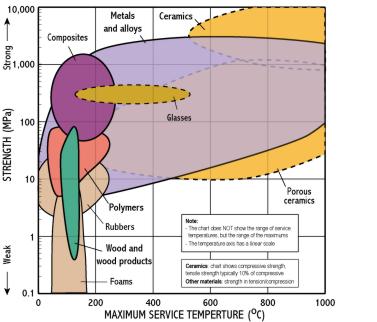

Nowadays polymers such as polypropylene (PP) and nylon are often used, but as the strength - maximum service temperature chart shows they must not be left standing in the pan or they will be ruined!

Disposable cups are often made from polystyrene (PS). This is surprising since the chart below shows the maximum use temperature is just below 100°C, but does explain why they go out of shape in boiling water! The single skin PS cups can get too hot to hold, but expanded polystyrene foam (EPS) cups don't have this problem as they are better thermal insulators. Unfortunately, many people don't like the 'feel' of EPS in the mouth. Recently, double skinned PS cups have been introduced which have an insulating airpocket between the layers - this solves both the problems, but they are more expensive to make.

|

|

Where a utensil is going to be in contact with heat for a long time, e.g. in the oven, the choice of materials is limited. The temperature chart shows only metals (e.g. stainless steel, cast iron, aluminium), glass and ceramics (such as pottery) will be suitable.

Plastics have revolutionised the kitchen. Thermoplastics such as ABS, PS and PP have replaced aluminium, zinc, pottery and glass for electrical appliances such as food mixers. They offer better hygiene and easier maintenance. Polycarbonate (PC) and PMMA (perspex) have replaced glass as the transparent materials of choice except where high temperatures are experienced. Melamine thermoset work surfaces provide attractive, hard-wearing, work surfaces which are resistant to heat and water. Polyethylene has replaced wood for the handles of many implements, while thermosets are used where the temperature might get hotter.

|

Everyone thinks of plates as being made from pottery (a porous ceramic). However, there are also other materials used: picnic plates are often made from polyethylene (PE) or melamine because they don't break so easily; disposable plates are usually made from paper (because it is cheap) - although this is often coated with a thin layer of polymer to prevent it going 'soggy' too quickly or the pattern smudging.

|

Stiffness from shape

Stiffness from shapeMost utensils need to be stiff, but the material that is used is only part of the story. Using clever shaping techniques, such as including stiffening ribs (easy with polymers), can add extra stiffness while using only slightly more material. Good examples of this are paper plates and polystyrene cups - both use corrugated edges.

|

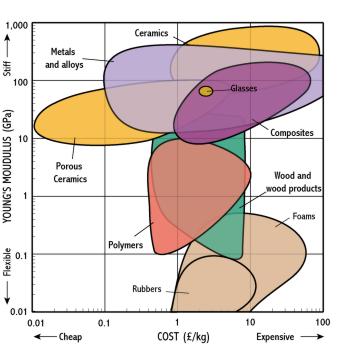

Polymers are relatively cheap, but the chart above shows that

some metals are cheaper. But does that mean polymer products are

more expensive? No! Although metals can be cheaper per kg,

they are lot more dense and we generally can't make metal things

very thin. As a result, the weight of a polymer utensil can be a

lot less than the weight of a metal utensil - so overall the

polymer product actually costs less!

In addition to the lower material costs, polymers are also

cheaper to manufacture. This is because there is usually only one

manufacturing step, whereas with metals there may be many (e.g.

casting, machining, grinding, joining etc.).

|