![]() Download this document in B&W

printable form (PDF

format).

Download this document in B&W

printable form (PDF

format).

|

These are usually made of steel because they need to be tough. However, they also need excellent wear resistance so are often coated with hard ceramics such as titanium carbide (TiC), boron nitride (BN) or diamond. Because the coating is not very thick, the tools can have excellent wear properties without losing toughness.

Ceramics are ideally suited to this task being extremely hard and available in the form of fine grit. Typically glass and silicon carbide of varying grit sizes are available.

Because a grinding wheel is meant to remove thin layers of material from other components but not to wear much itself, it needs to be as hard as possible. Grinding wheels cannot just be surface coated (like drill bits) since when the coating has gone the wheel will wear rapidly. The answer is to embed fine bits of ceramic in a softer matrix - this gives the wheel good toughness but also good wear resistance throughout its life.

|

|

Carbon steelsCarbon atoms are small compared with iron atoms and

fit in the gaps between them. This disrupts the iron

crystal structure making it harder. Carbon also reacts

with iron and other alloy elements to form hard

particles, which further increase strength. Heat treatment of steels The properties of steels (and many other metal alloys)

can be controlled by heat treatment. For carbon steels,

quenching causes a hard, brittle microstructure to be

formed. "Tempering" partly softens the steel

again, decreasing the strength (and hardness) but

recovering toughness - compare normalised, quenched, and

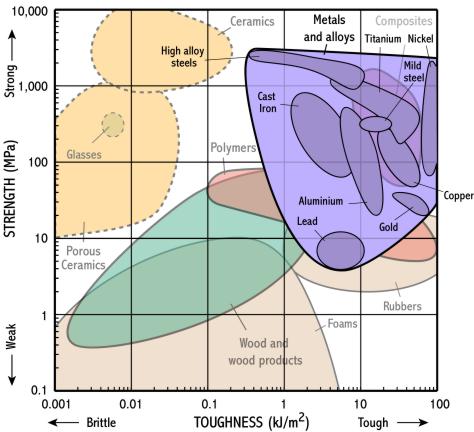

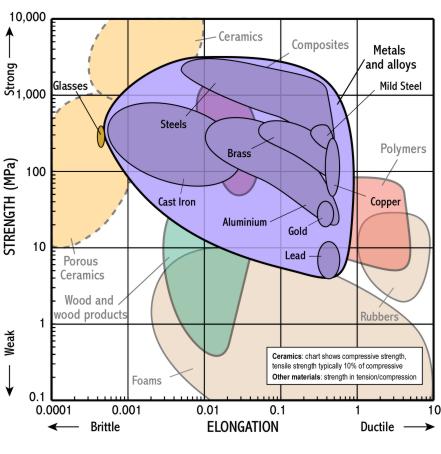

quenched & tempered 0.4%C steel on the chart. |

Hacksaw blades experience large forces and quite high temperatures whilst cutting metals. As a result, the body of the blade needs to be tough (so it remains flexible) and the cutting teeth need to be hard (so they don't wear out). One way of achieving this is to use a high carbon steel (0.7-1.4%C). The blade is stamped and the teeth formed in the softer normalised condition. The teeth are then locally quenched & tempered to increase their hardness. You should be able to work out roughly where normalised and quenched & tempered high carbon steels will be on the selection chart above using the information provided on the effect of alloying and heat treating steels.

A good hammer must have a high strength body to ensure good life, but this must be achieved with sufficient toughness or else it could splinter, possibly causing injury. They also need to be reasonably heavy! Carbon steels (e.g. 0.4%C) are used because they are relatively cheap. To get sufficient strength they are quenched. However the faces need to be tough so the hammer is then dipped in molten lead to achieve a good temper.

Forged versus castCast components often contain large crystal grains and

it is difficult to obtain a uniform microstructure. This

is due to the way crystals grow on cooling (as an example

look at the ice crystals on a lolly stick).

|

|